- Home >

- Voltage Drive or Current Drive

Voltage Drive or Current Drive

PWM Voltage Drive or Current Drive:

What is the best choice for Machine Vision Lighting?

|

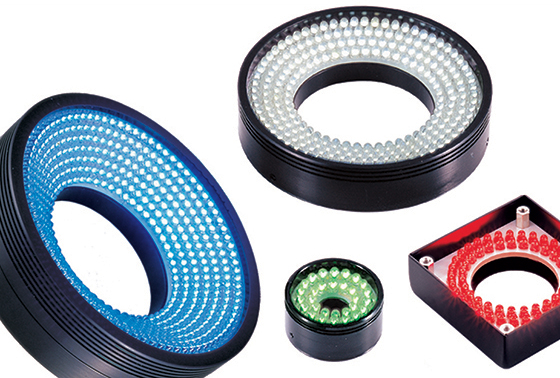

A great image is the essential starting point for a good machine vision system and a great image needs consistent illumination. Most machine vision systems use an LED illumination source with one of three drivers: a simple voltage drive, voltage drive with pulse width modulation (PWM) or a constant-current drive source. A simple voltage drive can be used to control brightness directly and may be adequate in some situations. However, voltage drive gives a more course adjustment than one would normally like and is fraught with accuracy and repeatability issues.

|

|

Although LED lights are often specified by the drive voltage, it is the current flowing through the light controls the brightness of machine vision lighting, not the supply voltage. For this reason, it's vital to carefully control the current flowing through the light. There are three main types of lighting controller: a voltage drive, a voltage drive with PWM and a constant current drive. Controllers based on voltage drive may be adequate for simple applications and can be economical, but these controllers can suffer from unpredictable illumination intensity due to power supply fluctuations, EMC interference or timing problems.

Learn more about driving LED lighting in the free white paper or hear a 5-minute podcast

Voltage Drive or Current Drive White Paper